| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : zmsh

Place of Origin : China

Material : Fused Quartz

Surface : Polished

Color : Transparent

Chemical Resistance : Highly resistant to acids and alkalis

Applications : Optical components, semiconductor processing, laboratory equipment, etc.

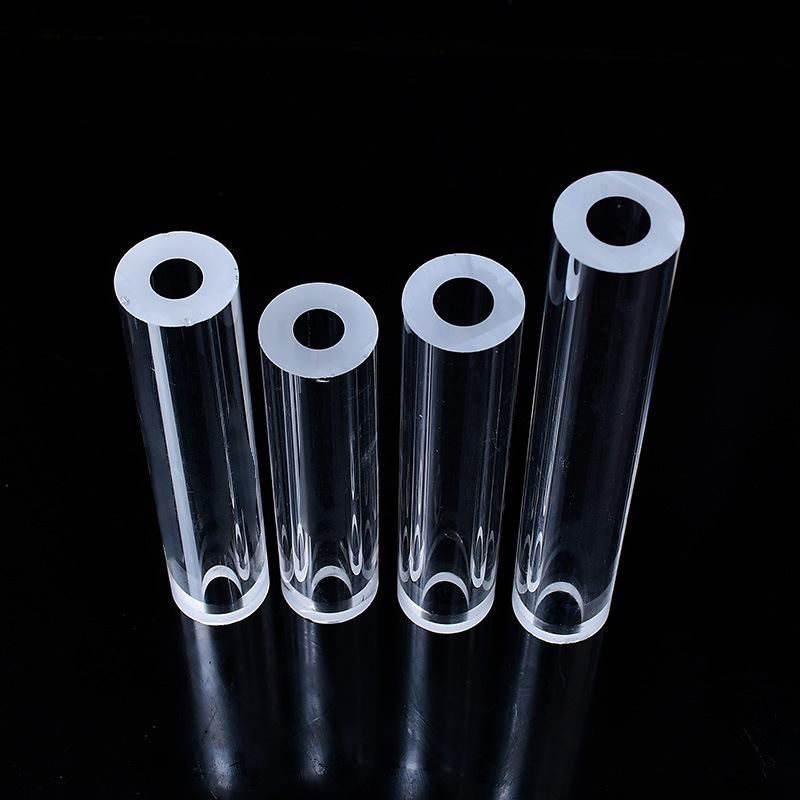

High Temperature Resistant Quartz Glass Tube — Thick-Walled, Transparent, Corrosion-Resistant

Quartz glass tubes are essential in modern high-performance systems where extreme thermal stability, chemical resistance, and optical transparency are required. This product features high-purity fused quartz formed into thick-walled, transparent tubes designed for demanding industrial, scientific, and laboratory applications.

Unlike standard glass materials, fused quartz exhibits a unique combination of properties—excellent thermal stability, low thermal expansion, superior corrosion resistance, and high optical clarity—making it suitable for use in aggressive chemical environments and high-temperature systems.

These quartz tubes are fabricated using advanced electric fusion techniques and precision-forming processes to ensure exceptional quality, uniform wall thickness, and tight dimensional tolerances. They can be further customized for a wide range of application-specific needs.

Applications

The high-temperature and corrosion-resistant quartz glass tube is highly versatile and widely used across many industries and research sectors:

1. Semiconductor Manufacturing

2. High-Temperature Furnaces

3. Chemical and Petrochemical Industry

4. UV and IR Optical Applications

5. Laboratory and Analytical Instruments

6. Solar and Energy Systems

Key Features

High Thermal Resistance

Chemical and Corrosion Resistance

High Optical Transparency

Thick-Walled Structural Strength

Customization and Machining Options

Specifications

| Property | Value / Range |

|---|---|

| Material | Fused Quartz (≥99.99% SiO₂) |

| Available Inner Diameters | 2 mm – 300 mm (customizable) |

| Wall Thickness | 1 mm – 10+ mm (standard and heavy-wall options) |

| Length Range | Up to 2,000 mm or per specification |

| Working Temperature | Continuous: up to 1100°C; Short-term: 1250°C |

| Softening Point | ~1730°C |

| Thermal Expansion Coefficient | ~0.55 × 10⁻⁶ /K |

| Transmission Range | 200 nm – 3,500 nm |

| Optical Transmission (600 nm) | >92% |

| Density | ~2.2 g/cm³ |

| Hardness (Mohs) | 5.5 – 6.5 |

| Knoop Hardness | ~610 kg/mm² |

| Electrical Resistivity | ~10⁷ – 10¹⁴ Ω·cm (depending on temperature) |

| Packaging | Cleanroom-sealed or industrial carton |

| Certifications | RoHS, REACH, ISO9001 |

Q&A

Q1: What is the difference between thick-walled and standard quartz tubes?

Thick-walled quartz tubes offer increased mechanical strength, pressure resistance, and durability in high-stress environments. They are ideal for vacuum systems, pressurized reactors, and high-temperature lamp housings.

Q2: Is the quartz tube suitable for direct flame or plasma exposure?

Yes, our fused quartz tubes can tolerate open flame and high-temperature plasma exposure, provided temperature ramping is controlled. They are commonly used in torch systems, flame reactors, and induction heating environments.

Q3: Can these tubes be customized for laboratory glassware or vacuum feedthroughs?

Absolutely. We offer CNC machining, precision cutting, flaring, grinding, and drilling for custom assemblies including feedthroughs, condenser jackets, and diffusion tubes.

Q4: How does the optical quality compare to other materials like borosilicate or sapphire?

Fused quartz offers superior UV and IR transmission over borosilicate, along with better thermal and chemical resistance. While sapphire provides even higher strength and hardness, quartz is more cost-effective and easier to fabricate.

Q5: What are the cleaning and maintenance requirements?

Quartz tubes should be cleaned with dilute acids or pure solvents. Avoid using abrasives. Rinse with deionized water and dry in a dust-free environment. For high-purity applications, cleanroom handling and degassing can be requested.

Q6: What is the typical lead time for custom orders?

|

|

High Temperature Resistant Quartz Glass Tube Thick Wall Transparent Corrosion Resistant Glass Images |